CUSTOM ROTOMOLDING SERVICE

Rotational molding, also known as rotomolding, is a highly versatile manufacturing process that is commonly used to produce a wide range of plastic products. This process involves heating plastic resin in a mold and rotating it to evenly distribute the material and create a seamless, uniform product. In this comprehensive guide, we will explore the custom rotomolding process in detail, covering everything from the design phase to the finished product.

The Design Phase: Creating the Perfect Part

The first step in the custom rotomolding process is designing the part. This is a critical phase that requires careful planning and attention to detail. At this stage, we will take into account all the variables to optimize the whole value chain of the product to the full lifecycle including engineering, sourcing, packaging, logistics, production, assembly, sales and marketing and after sales service.

To begin the design process, we work closely with our clients to understand their unique needs and requirements. We then use this information to create a detailed 3D model and/or a printed 3D model of the part using specialized software and equipment. This allows us to identify any potential issues or design flaws before the mold is created, saving time and money in the long run.

Creating the Mold: Precision and Expertise

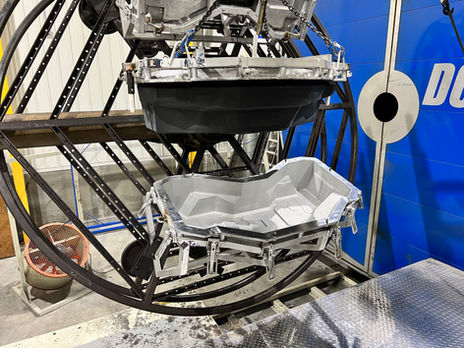

Once the part design is finalized, we move on to creating the mold itself. This is a highly technical process that requires experience, precision and expertise. The mold is typically made from aluminum and must be CNC machined to exact specifications.The mold is essentially a negative image of the finished product, so it must be designed with precision to ensure the final product meets the exact specifications.

During the mold creation process, we pay close attention to every detail to ensure a long life span of the mold up to 30,000 cycles with minimum maintenance cost. Quality parts come from a quality mold.

The Manufacturing Process: Rotomolding in Action

With the mold in place, we are ready to begin the custom rotomolding process. This involves heating the plastic resin until it reaches it’s melting point and then rotating the mold to evenly distribute the material.

The rotation process is critical to the success of the custom rotomolding process. The mold is rotated in multiple directions to ensure the plastic resin is evenly distributed, resulting in a seamless and uniform finished product.

Finishing and Quality Control: Attention to Detail

Once the plastic has cooled and solidified, we carefully remove the finished product from the mold and proceed to the finishing process. Our attention to detail during this stage involves trimming any excess material, adding any necessary hardware or components, and applying any finishing touches to ensure that the final product meets your specifications.

At Rotoplast, quality control is of utmost importance. We hold ourselves to the highest standards of quality and are proud to be the only custom molder in Quebec ISO 9001 certified. Our quality control measures begin with inspecting the mold before production and continue throughout the entire custom rotomolding process. We perform rigorous inspections on the finished product to ensure that it meets all necessary requirements and is of the highest quality. This commitment to quality allows us to consistently deliver products that meet or exceed our customers' expectations.

The Benefits of Custom Rotomolding

Custom rotomolding offers a wide range of benefits over other molding processes. One of the biggest advantages is the ability to create complex shapes and designs that would be difficult or impossible to produce using other methods. Also, the rotational molding will create stress-free parts that have a very high impact resistance at hot or cold temperatures and that are suitable for rugged high-end products.

Custom rotomolding is also highly cost-effective, particularly for low-volume production runs. This is because the mold investment is fairly low compared to blow molding and injection molding, reducing the overall cost of production.

Finally, custom rotomolding is an eco-friendly manufacturing process that produces little to no waste and the life span of the plastic parts is up to many decades. This makes it an ideal choice for companies looking to reduce their environmental impact.

Choose Custom Rotomolding for Your Manufacturing Needs

In conclusion, custom rotomolding is a highly versatile and cost-effective manufacturing process that offers a wide range of benefits over traditional molding methods. By working with a skilled and experienced manufacturer, you can create high-quality products that meet your exact specifications.

|  |  |

|---|